-

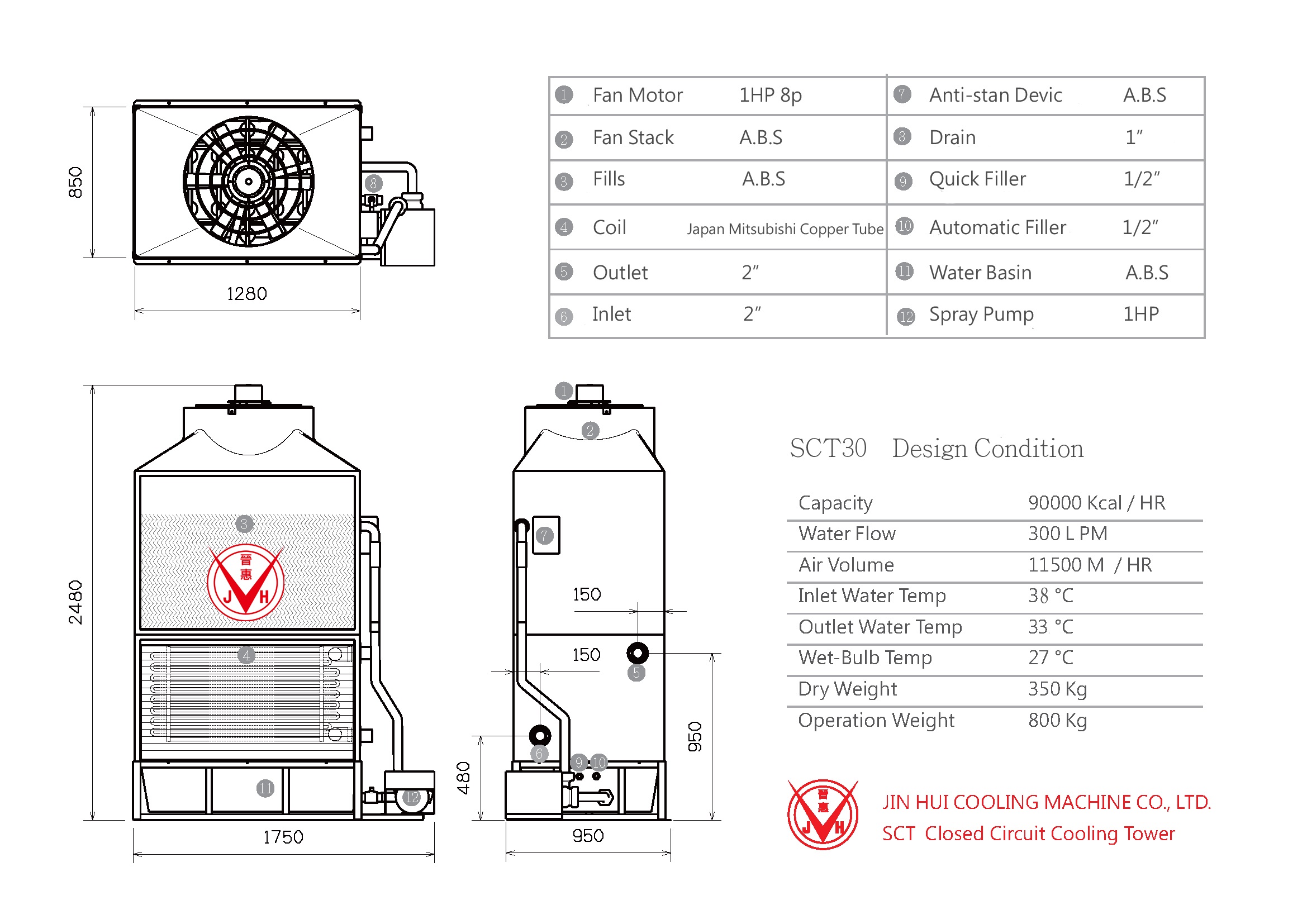

Small & eco-friendly closed circuit cooling tower (SCT-30) 90000 Kcal/h

Small & eco-friendly closed circuit cooling tower (SCT-30) 90000 Kcal/h

Small & eco-friendly closed circuit cooling tower (SCT-30) 90000 Kcal/h

Small & eco-friendly closed circuit cooling tower (SCT-30) 90000 Kcal/h

-

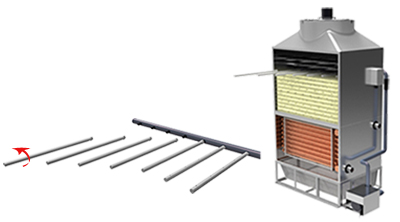

SCT-30 Parallel design

SCT-30 Parallel design

SCT-30 Parallel design

SCT-30 Parallel design

-

SCT-30 Transport 、package

SCT-30 Transport 、package

SCT-30 Transport 、package

SCT-30 Transport 、package

-

SCT-30 3 units series design

SCT-30 3 units series design

SCT-30 3 units series design

SCT-30 3 units series design

-

Space saving

Space saving

Space saving

Space saving

-

SCT-30 Stainless steel material

SCT-30 Stainless steel material

SCT-30 Stainless steel material

SCT-30 Stainless steel material

-

SCT-30 Plenty units parallel design on cockloft

SCT-30 Plenty units parallel design on cockloft

SCT-30 Plenty units parallel design on cockloft

SCT-30 Plenty units parallel design on cockloft

https://cooling-towers.com.tw/product-2/closed-circuit-cooling-tower/easy-maintain-sct/sct-30-90000-kcal-h#sigProId5c7b094a95

Feature

Cooling capacity:

90,000 Kcal/h or 104.6 KW

Reusable Fills

Stainless steel #304 Shell

Space Saving

Easy Maintenance

Electronic Type

Anti-stain Device

Heat Exchanger Coil:

Mitsubishi Copper Tube

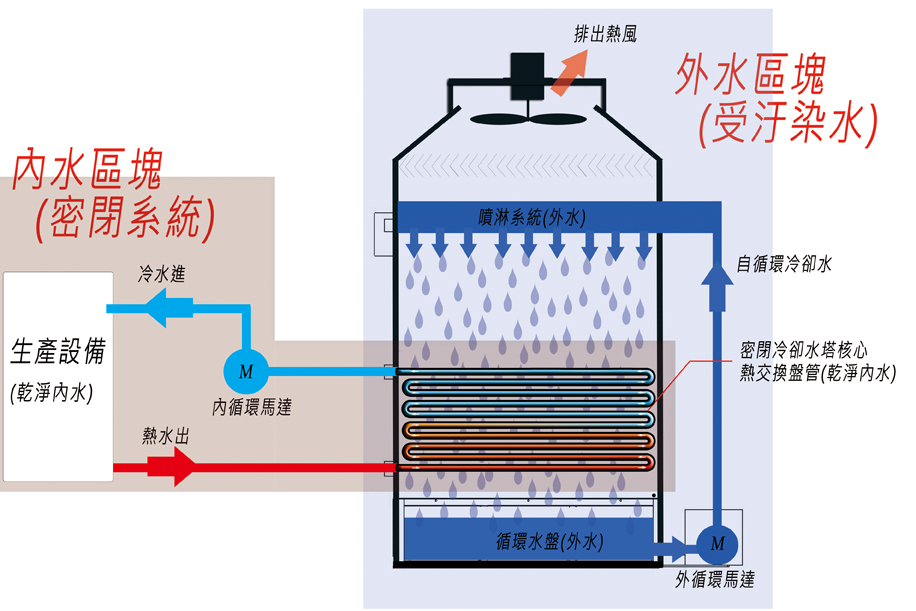

Description (What is Closed Circuit Cooling Tower?)

SCT-30 is a small size stainless steel Closed Circuit Cooling Tower of SCT series, applicable to small and medium size one-to-one equipment for cooling , such as high frequency furnace, water-cooled air compressor, industrial chiller, or one-to-many plastic injection system, it use inside and outside water separate principle, making your machine’s water quality clean, SCT series also use stainless steel material, which is easy to cleaned and maintained without supplies. This is a Closed Circuit Cooling Tower not only convenient, but also beautiful and environmentally friendly.

Application

- Plastic injection molding, blow molding machine

- Low, medium and high-induction melting furnace

- Forging

- Air Compressor

- Chiller

- Cooling facility for transferring hot water to cold water

- Environment pollution reduces mechanical efficiency

- Tube blocked by CaCo3 and dirty water

Specification

| Cooling Capacity (38°C to 33°C Wet bulb 27°C) | 90,000 Kcal/h 300 LPM |

| Fan Motor Type | Axial flow fan (8P low noise) |

| Fan Shell Material | Anti-UV& One piece fabricated (ABS material) |

| Shell Material | Material: Stainless steel #304 |

| Machine Base Material | Material: Stainless steel #304 |

| Electronic type anti-stain device | To decrease limescale attaching on copper tube |

| Water Basin Material | Anti-UV& One piece fabricated (ABS material) |

| Heat Exchanger Coil | Japan Mitsubishi Copper Tube |

| Fan Electricity | 0.75 KW x 8P |

| Fan Volume | 11500 m³/hr |

| Spray Pump Electricity | 0.75 KW |

| Net Weight | 350 KG |

| Dimensions (L*W*H cm) | 1750(L) x 950(W) x 22480(H) |

Details

Cooling fan stack & Motor

SCT-30 with low-sound fan motor and one piece ABS fan stack could reduce noise and avoid vibration problem compare to traditional type.

SCT-30 with low-sound fan motor and one piece ABS fan stack could reduce noise and avoid vibration problem compare to traditional type.

Shell material

SCT-30 with stainless steel SUS304 structure adopts one-piece fabricated design is firm and great-looking!

Easy to dismount

SCT-30 is an eco-friendly and sustainable closed circuit cooling tower with SUS304 shell and detachable design for simple maintenance to reduce labor and technical cost.

SCT-30 is an eco-friendly and sustainable closed circuit cooling tower with SUS304 shell and detachable design for simple maintenance to reduce labor and technical cost.

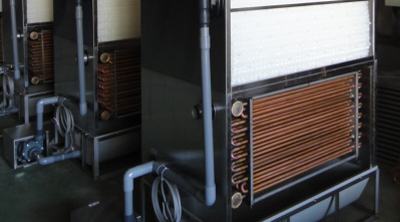

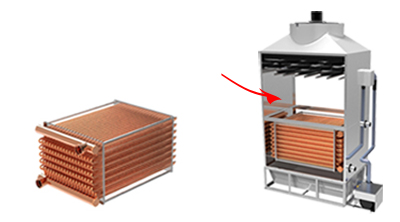

Heat exchange coil

Heat exchange coil made of Japan Mitsubishi copper tube has high thermal conductivity and great ductility. It’s suitable for small closed type cooling system to maximize heat exchange efficiency.

Heat exchange coil made of Japan Mitsubishi copper tube has high thermal conductivity and great ductility. It’s suitable for small closed type cooling system to maximize heat exchange efficiency.

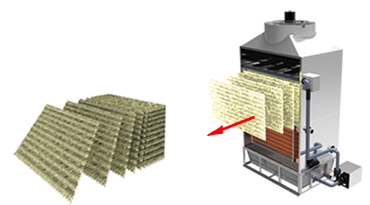

Fill & Water Distribution System

Sprinkler system with patented flap was attached on SCT-30. Moreover, ABS heat dissipation fill features high toughness, impact resistance, beat bearing and reusable.

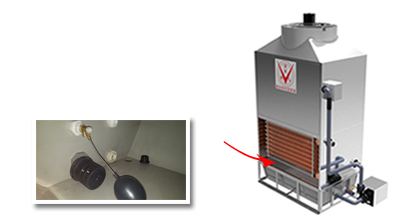

Electronic Anti-stain Device

Under fixed concentration, SCT-30 with electronic anti-scale device lowers the potential of building up limescale on coil by separating ions.

Under fixed concentration, SCT-30 with electronic anti-scale device lowers the potential of building up limescale on coil by separating ions.

Base

Base support that utilizes 2.6mm SUS #304 corner bracket is durable and firm to ensure working stability.

Base support that utilizes 2.6mm SUS #304 corner bracket is durable and firm to ensure working stability.

Water Basin

Water basin made by ABS one-piece fabricated mold distributes weight of cooling tower evenly. Furthermore, bevel face design of tower’s bottom helps to get rid of dirty easily.

Water basin made by ABS one-piece fabricated mold distributes weight of cooling tower evenly. Furthermore, bevel face design of tower’s bottom helps to get rid of dirty easily.

Pump & SUS #304 Cover

External circulator motor for SCT-30 takes advantage of high-flow circulator pump and SUS304 waterproof cover to reduce the potential of producing rust for staying outdoors.

External circulator motor for SCT-30 takes advantage of high-flow circulator pump and SUS304 waterproof cover to reduce the potential of producing rust for staying outdoors.

Maintenance

Step1: Water Distribution Tube

Step2: Fill

Fill under the sprinkler tube are piece by piece design. Take it out by screw driver and beat it to get rid of the dirt and scale deposits. Then put the fill back.

Step3: Heat Exchange Coil

Step4: Water Basin

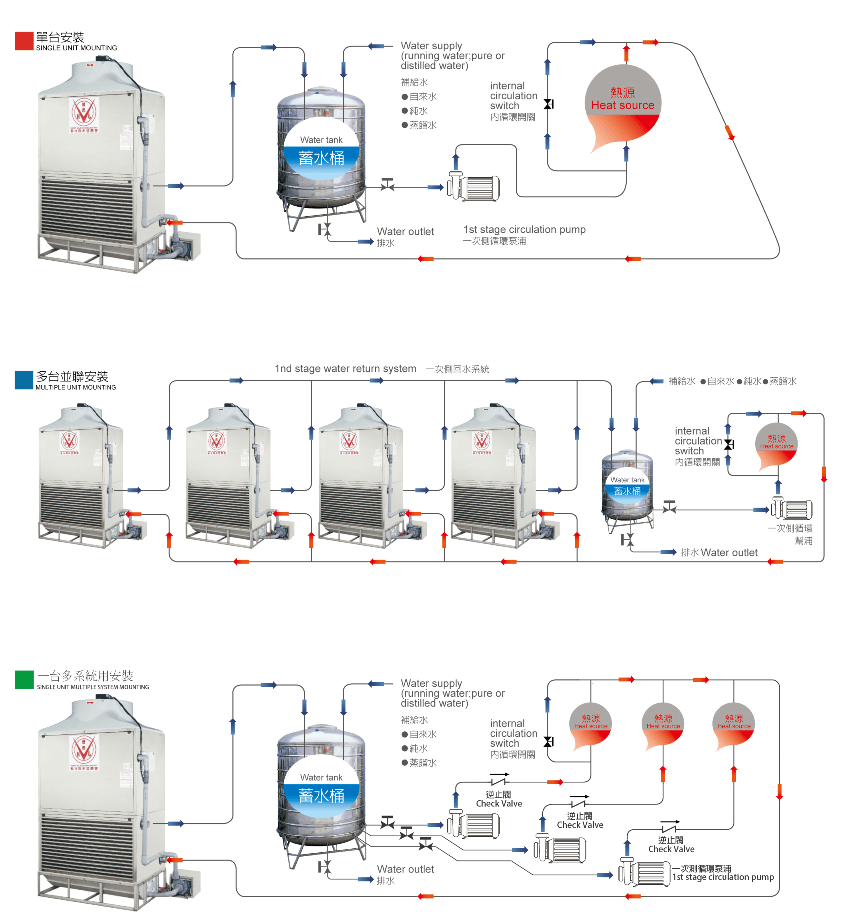

SCT-30 Closed Loop Cooling Tower Pipe Layout

PCT-15-40 with PE coil design patent ensures cooling fluid clean and prevents acid corrosion. It is economic closed cooling system special for low thermal cooling.