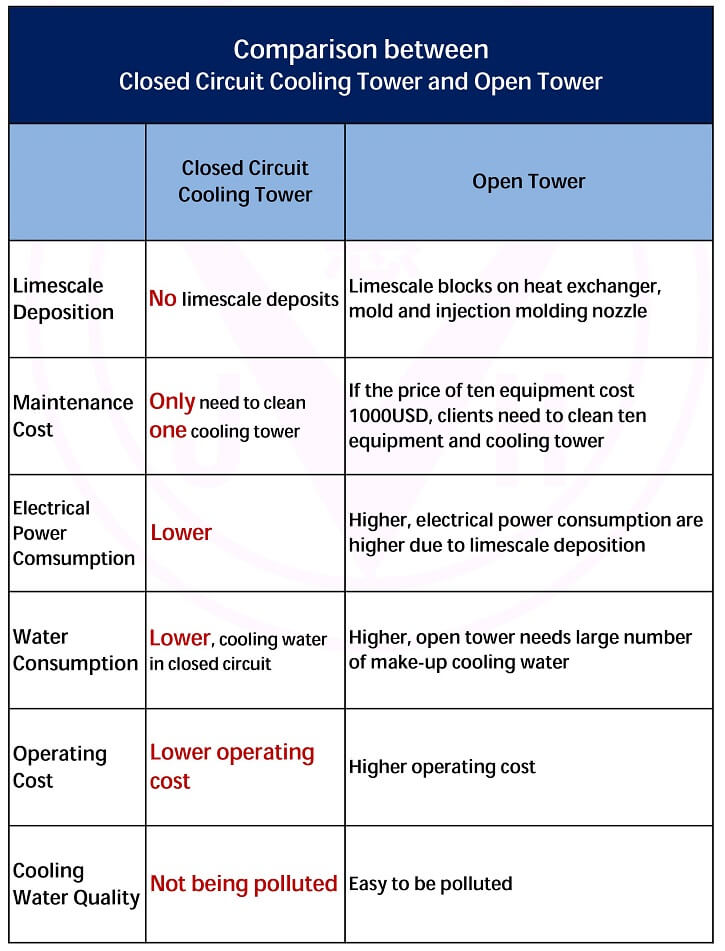

Limescale influences facility and heat exchange rate.

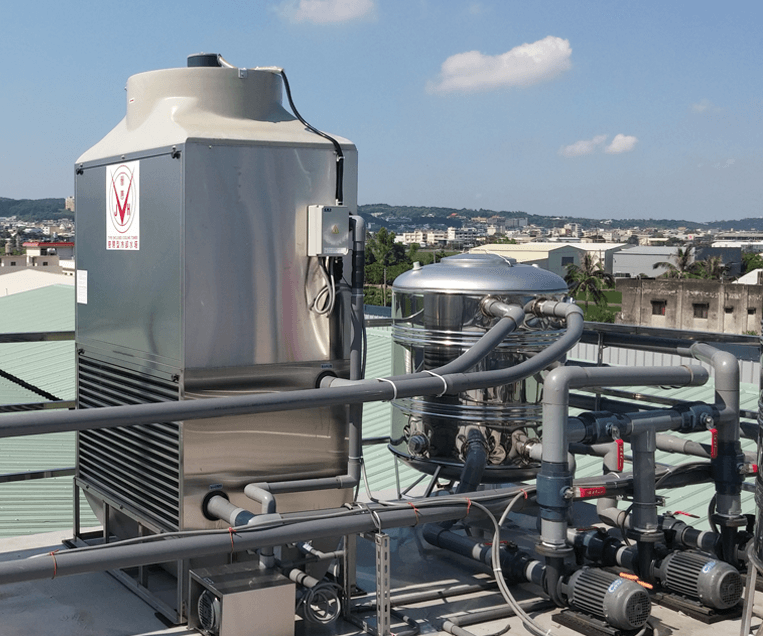

Jin Hui closed loop cooling tower specilizes in solving troubles of limescale.

New design of advanced techniques, it’s unnecessary to shut down for cleaning and prevent machine from acid washing by simple maintenance steps.

Plastic manufacture customer often encounter limescale problem happened in the plastic injection equipments, it usually make machine unable to operate, production unstable, or even shut down.

Jin Hui owns the most customers in plastic industry. The most important reason is that lots of mineral exist in water, contributing to temperature control problem and unstable product yield rate during plastic manufacturing process.

Customers like to ask us how to solve troubles of limescale. First, we will explain the following to them : 1.Dirt entered from the cooling tower. 2. To eradicate limescale, cooling tower is the key.

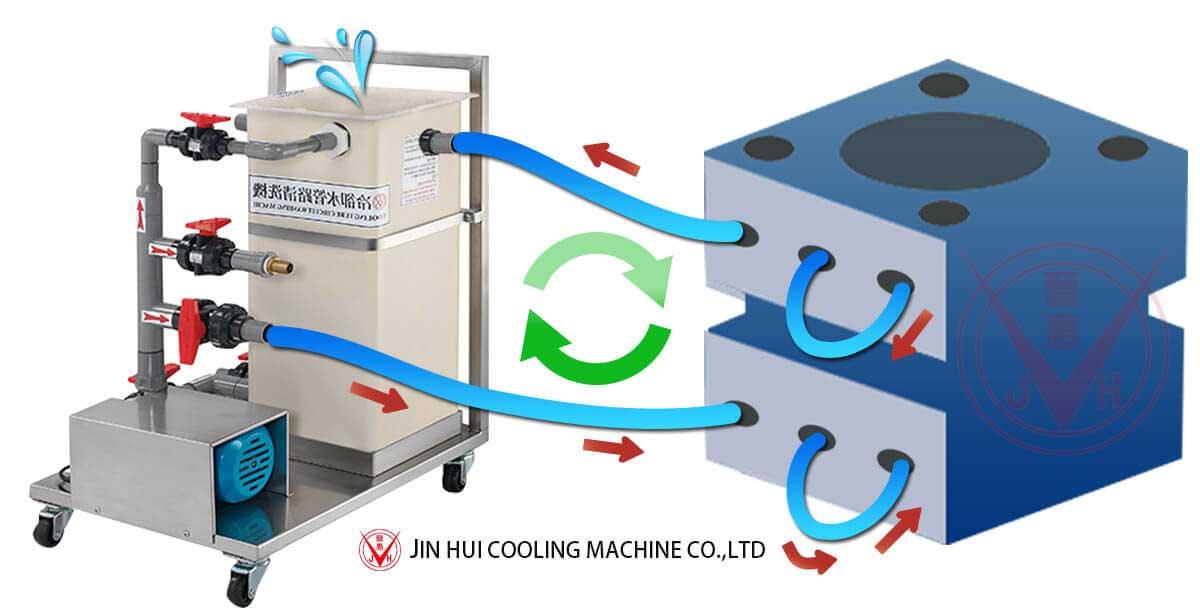

In metal forming, there is a permanent mold casting which employs reusable mole. Differently from the one-time mold, there usually are a mold cooling and a die casting processes. The cooling processes involved include!