https://cooling-towers.com.tw/product-2/closed-circuit-cooling-tower/easy-maintain-sct/sct-60-180000-kcal-h#sigProId42bab5585c

Feature

Cooling capacity:

180,000 Kcal/h or 209.3 KW

Stainless Steel #304 Shell

Heat Exchanger Coil:

Mitsubishi Copper Tube

Easy Maintenance

Electronic Anti-Stain

Reusable Fills

Space Saving

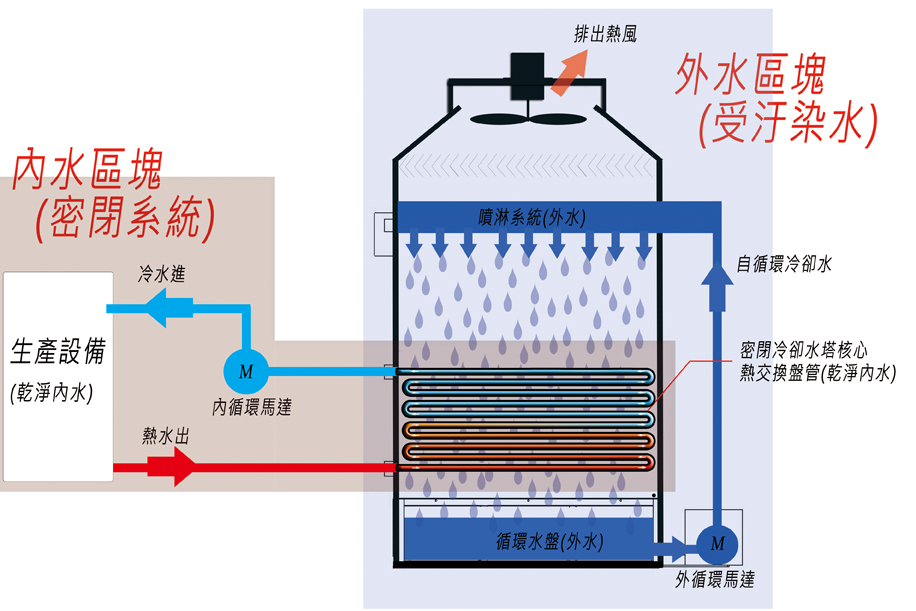

Description(What is Closed Circuit Cooling Tower?)

SCT-60 is a medium-size stainless steel Closed Circuit Cooling Tower of SCT series, applicable to one-to-one industrial equipment for cooling, such as forging and casting equipment. It also used in medium and large scale plastic molding factory, making your equipment clean without limescale. SCT series also use stainless steel material, so that the machine can be regularly clean and maintenance without supplies, modular accessories can be fast to deal with maintenance problems, this is a Closed Circuit Cooling Tower not only convenient, but also beautiful and environmentally friendly.

Application

- Plastic injection molding, blow molding machine

- Low, medium and high-induction melting furnace

- Forging

- Air Compressor

- Chiller

- Cooling facility for transferring hot water to cold water

- Environment pollution reduces mechanical efficiency

- Tube blocked by CaCo3 and dirty water

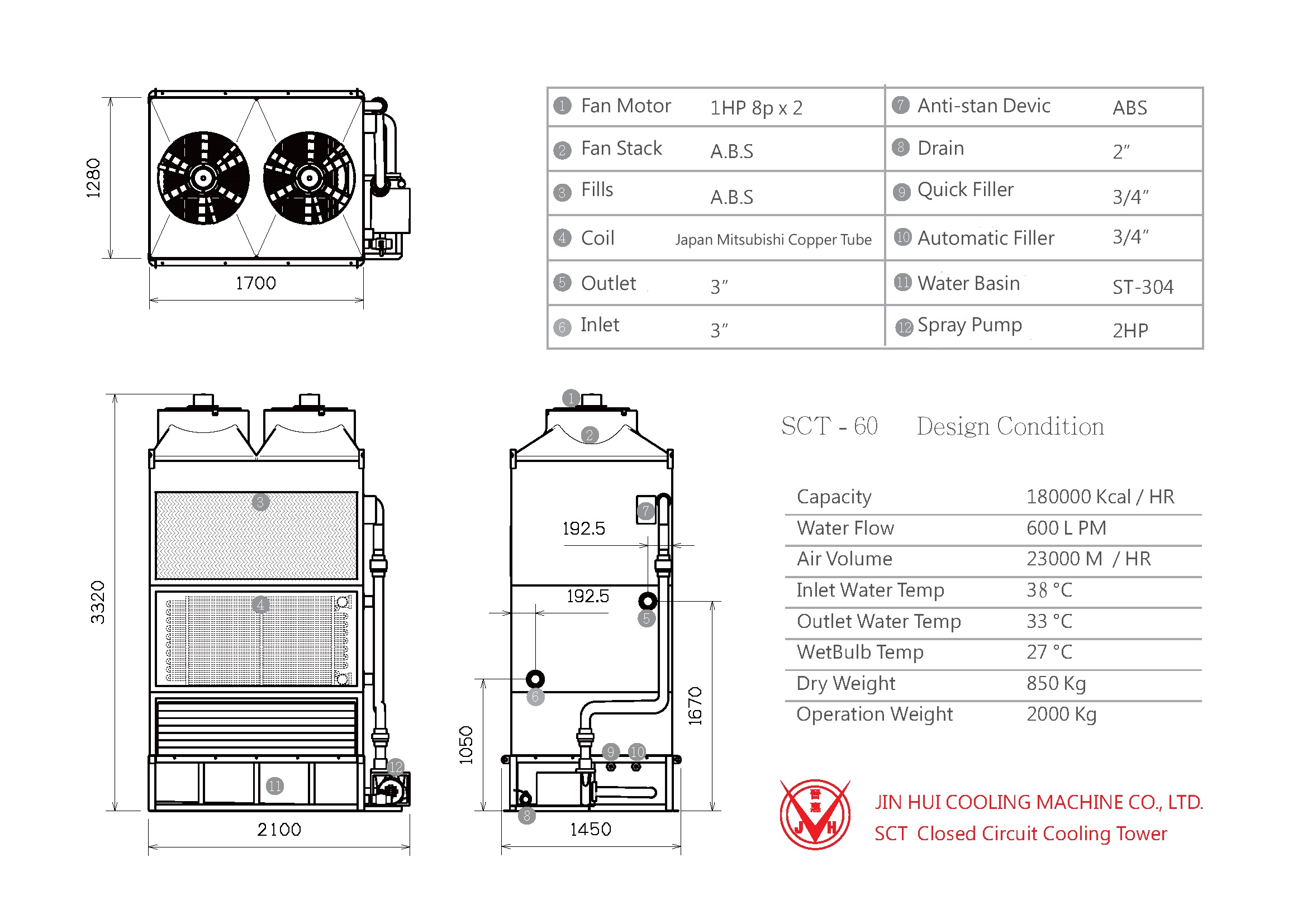

Specification

| Cooling Capacity (38°C to 33°C Wet bulb 27°C) | 180,000 Kcal/h 600 LPM |

| Fan Motor Type | Axial flow fan (8P low noise) |

| Fan Shell Material | Anti-UV& One piece fabricated (ABS material) |

| Shell Material | Material: Stainless steel #304 |

| Machine Base Material | Material: Stainless steel #304 |

| Electronic type anti-stain device | To decrease limescale attaching on copper tube |

| Water Basin Material | Anti-UV& One piece fabricated (ABS material) |

| Heat Exchanger Coil | Japan Mitsubishi Copper Tube |

| Fan Electricity | 0.75 KW 8P x 2 |

| Fan Volume | 11500 m³/hr x 2 |

| Spray Pump Electricity | 1.5 KW |

| Net Weight | 850 KG |

| Dimensions (L*W*H cm) | 2100(L) x 1450(W) x 3320(H) |

Details

Cooling fan stack & Motor

SCT-60 with low-sound fan motor and ABS one-piece fabricated fan stack not only lowers noise but also avoids vibration problem, as compared to traditional type.

SCT-60 with low-sound fan motor and ABS one-piece fabricated fan stack not only lowers noise but also avoids vibration problem, as compared to traditional type.

Shell material

SCT-60 with stainless steel SUS304 structure adopts one-piece fabricated design is firm and great-looking!

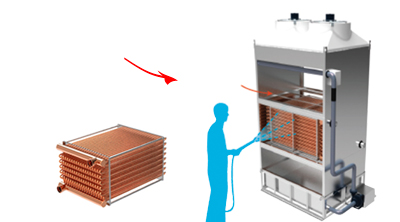

Easy to dismount

SCT-60 is an eco-friendly and sustainable closed circuit cooling tower with SUS304 shell and detachable design for simple maintenance to reduce labor and technical cost.

SCT-60 is an eco-friendly and sustainable closed circuit cooling tower with SUS304 shell and detachable design for simple maintenance to reduce labor and technical cost.

Heat exchange coil

Heat exchange coil made of Japan Mitsubishi copper tube has high thermal conductivity and great ductility. It’s suitable for small closed type cooling system to maximize heat exchange efficiency.

Heat exchange coil made of Japan Mitsubishi copper tube has high thermal conductivity and great ductility. It’s suitable for small closed type cooling system to maximize heat exchange efficiency.

Fill & Water Distribution System

Sprinkler system with patented flap was attached on SCT-60. Moreover, ABS heat dissipation fill features high toughness, impact resistance, beat bearing and reusable.

Electronic Anti-stain Device

Under fixed concentration, SCT-60 with electronic anti-scale device lowers the potential of building up limescale on coil by separating ions.

Under fixed concentration, SCT-60 with electronic anti-scale device lowers the potential of building up limescale on coil by separating ions.

Base

Base support that utilizes 2.6mm SUS #304 corner bracket is durable and firm to ensure working stability.

Base support that utilizes 2.6mm SUS #304 corner bracket is durable and firm to ensure working stability.

Water Basin

Water basin made by ABS one-piece fabricated mold distributes weight of cooling tower evenly. Furthermore, bevel face design of tower’s bottom helps to get rid of dirty easily.

Water basin made by ABS one-piece fabricated mold distributes weight of cooling tower evenly. Furthermore, bevel face design of tower’s bottom helps to get rid of dirty easily.

Pump & SUS #304 Cover

External circulator motor for SCT-60 takes advantage of high-flow circulator pump and SUS304 waterproof cover to reduce the potential of producing rust for staying outdoors.

External circulator motor for SCT-60 takes advantage of high-flow circulator pump and SUS304 waterproof cover to reduce the potential of producing rust for staying outdoors.

Maintenance

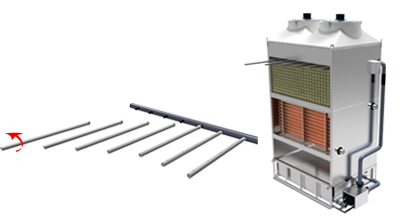

Step1: Water Distribution Tube

First, open the device case and turn down the sprinkler pipe 90∘counterclockwise for maintenance. After cleaning, put all the parts back and make sure the spray hole upward.

First, open the device case and turn down the sprinkler pipe 90∘counterclockwise for maintenance. After cleaning, put all the parts back and make sure the spray hole upward.

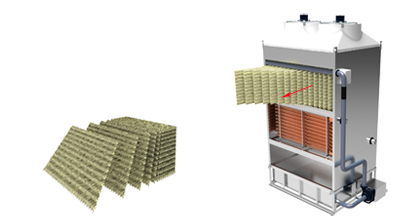

Step2: Fill

Fill under the sprinkler tube are piece by piece design. Take it out by screw driver and beat it to get rid of the dirt and scale deposits. Then put the fill back.

Fill under the sprinkler tube are piece by piece design. Take it out by screw driver and beat it to get rid of the dirt and scale deposits. Then put the fill back.

Step3: Heat Exchanger Coil

Open the intake louver underneath then use high pressure washer to rinse out the dirt and deposition attached on the coil. PS: When limescale problem occurs, please contact us for professional support.

Open the intake louver underneath then use high pressure washer to rinse out the dirt and deposition attached on the coil. PS: When limescale problem occurs, please contact us for professional support.

Step4: Water Basin

After finishing all cleaning steps above, there will be plenty of deposition, impurities and calcium carbonate in the water basin. Furthermore, to avoid contaminating the circulating system, make sure that water basin is clean before machine operates. PS: Regularly discharging external water of basin is helpful for reducing the increase of calcium ion concentration besides lowering 70% chance of forming limescale.

After finishing all cleaning steps above, there will be plenty of deposition, impurities and calcium carbonate in the water basin. Furthermore, to avoid contaminating the circulating system, make sure that water basin is clean before machine operates. PS: Regularly discharging external water of basin is helpful for reducing the increase of calcium ion concentration besides lowering 70% chance of forming limescale.

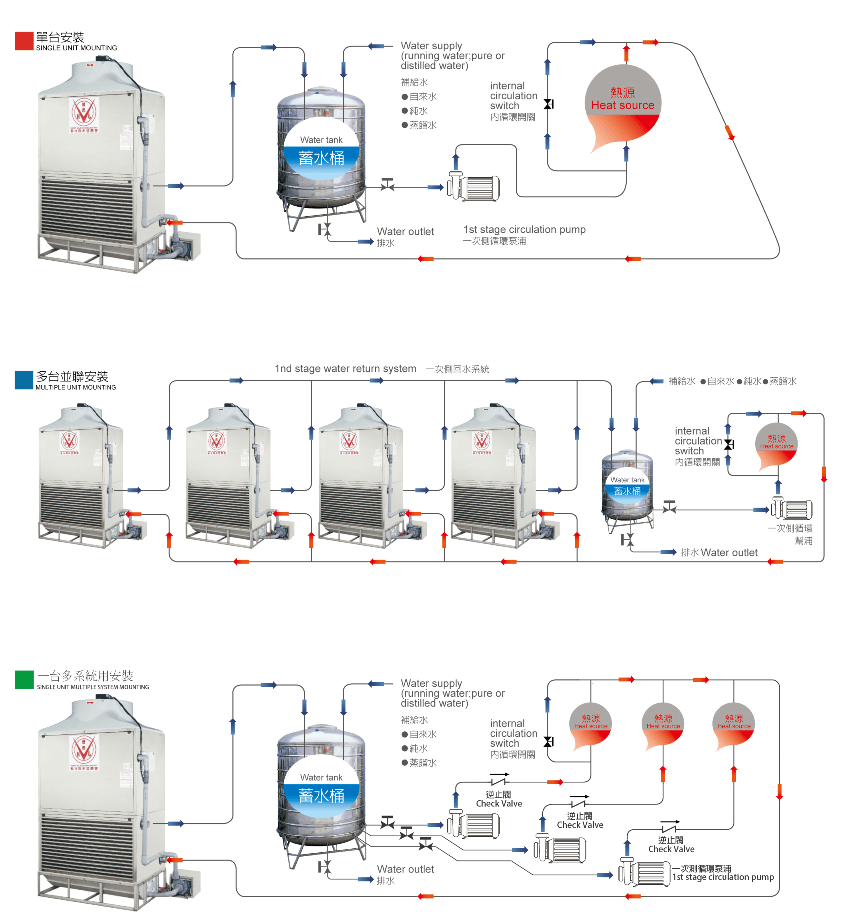

SCT-60 closed loop cooling tower pipe layout

HCT-50-500 could be customized in super galvanize aluminize plate or # 304 stainless steel and adopt stainless steel heat exchanger. Fan & sprinkler in same direction design could avoid water spraying out.

PCT-15-40 with PE coil design patent ensures cooling fluid clean and prevents acid corrosion. It is economic closed cooling system special for low thermal cooling.

Welcome to know our technology. We are a professional cooling manufacturer.