-

Mixed flow & high efficiency closed type cooling tower

Mixed flow & high efficiency closed type cooling tower

Mixed flow & high efficiency closed type cooling tower

Mixed flow & high efficiency closed type cooling tower

-

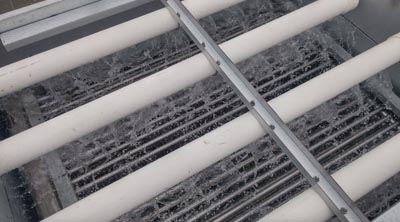

Our heat exchange coils are made by SUS

Our heat exchange coils are made by SUS

Our heat exchange coils are made by SUS

Our heat exchange coils are made by SUS

-

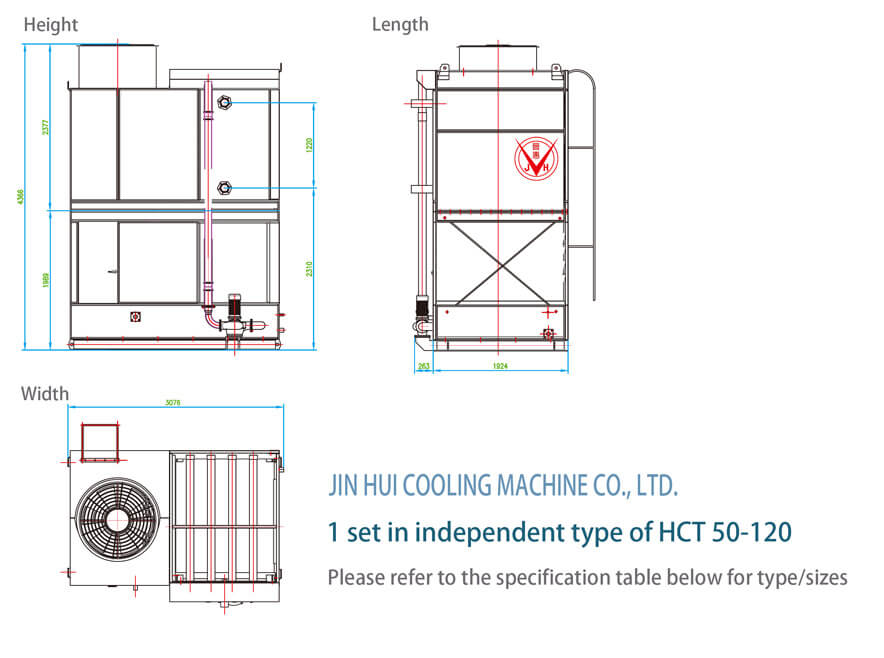

Installing HCT-50-500

Installing HCT-50-500

Installing HCT-50-500

Installing HCT-50-500

-

Huge space for easy work

Huge space for easy work

Huge space for easy work

Huge space for easy work

-

2mm galvalume steel sheet can extend its life

2mm galvalume steel sheet can extend its life

2mm galvalume steel sheet can extend its life

2mm galvalume steel sheet can extend its life

https://cooling-towers.com.tw/product-2/closed-circuit-cooling-tower/hct-50-250#sigProId57a9419b59

Feature

Cooling Capacity:

180,000 Kcal to 1000,000 Kcal

Fan & sprinkler in same direction design

could avoid water spraying out

Galvanized aluminum body

(#304 stainless steel is available)

High efficiency

double heat dissipation area

Big maintenance space

Dechargeable filler design

#304 stainless steel tube

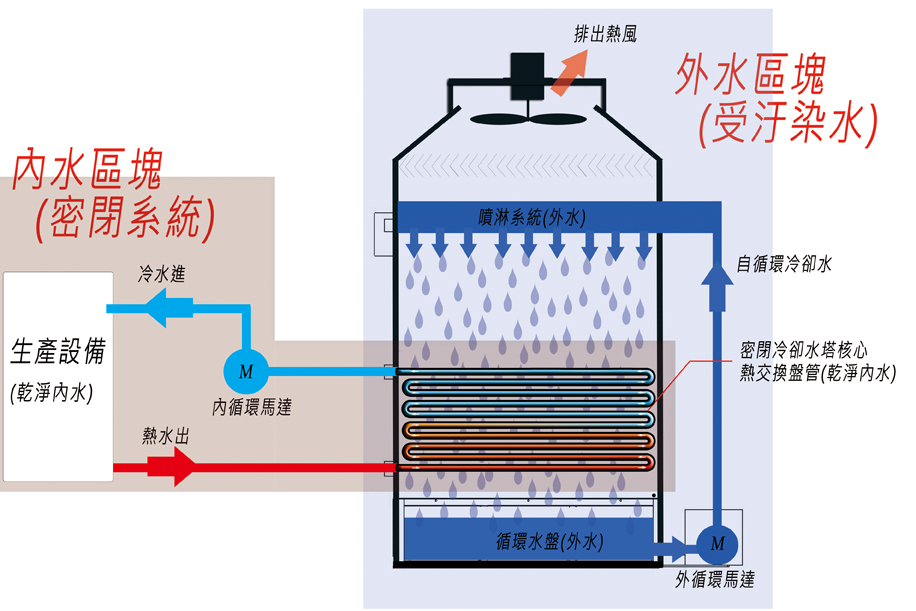

Description ( What is closed type cooling tower? )

HCT Series is the largest line of closed circuit cooling tower. This newest design of double air intake system not only doubles the heat dissipation area but also maximizes the coverage of coil in water distribution system for lowering the possibility of building up limescale.

HCT with alumi-zinc shell achieves the longest life-span and anti-corrosion. Customers can also choose SUS #304 as shell material. Furthermore, the greatest strength of HCT Series is, its heat exchanger coil with SUS #304 material is able to extend life-span and be suited to use in specific environment.

Application

- Plastic injection molding, blow molding machine

- Low, medium and high-induction melting furnace

- Forging

- Air Compressor

- Chiller

- Cooling system for transferring hot water to cold water

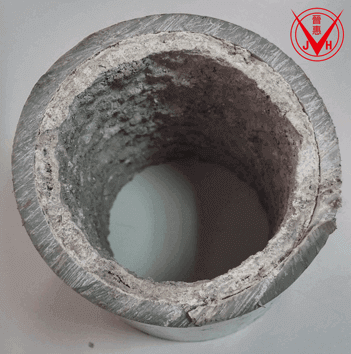

- Environment pollution lowers mechanical efficiency

- Tube blocked by calcium carbonate (CaCo3)

Specification

| Model | Cooling Capacity(Kcal/h) | Water Flow(m3/h) | Fan Motor(KW) | Air Flow(m3/h) | Pump Motor(KW) | Amount Of Water(m3/h) | Water Pipe Diameter(DN/mm) | Weight(kg) | Dimension (LxWxH)(mm) |

| HCT-50 | 150000 | 30-32 | 3 | 35000x1 | 1.1 | 45 | DN80 | 2000 | 1925x2380x4220 |

| HCT-60 | 180000 | 40-43 | 4 | 45000x1 | 1.1 | 45 | DN100 | 2200 | 1925x2380x4220 |

| HCT-80 | 240000 | 49-51 | 5.5 | 65000x1 | 1.1 | 45 | DN100 | 3150 | 1925x2580x4220 |

| HCT-100 | 300000 | 59-61 | 5.5 | 65000x1 | 1.1 | 65 | DN100 | 3350 | 1925x2980x4220 |

| HCT-120 | 360000 | 70-72 | 5.5 | 65000x1 | 1.1 | 65 | DN100 | 4150 | 1925x2980x4220 |

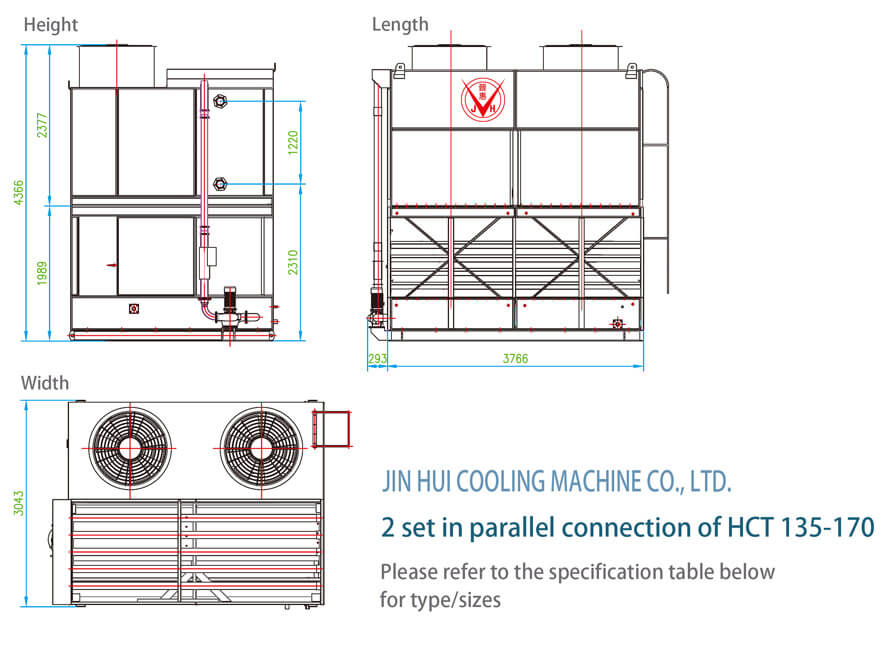

| HCT-135 | 400000 | 80-82 | 4 | 45000x2 | 2.2 | 84 | DN100 | 4700 | 3770x2200x4240 |

| HCT-150 | 450000 | 90-93 | 4 | 45000x2 | 2.2 | 84 | DN125 | 4950 | 3770x2200x4910 |

| HCT-170 | 510000 | 102-105 | 4 | 45000x2 | 3 | 120 | DN125 | 8100 | 3770x2200x4910 |

| HCT-200 | 600000 | 125-128 | 4 | 45000x3 | 3 | 120 | 2DN100 | 5500 | 4240x2200x4910 |

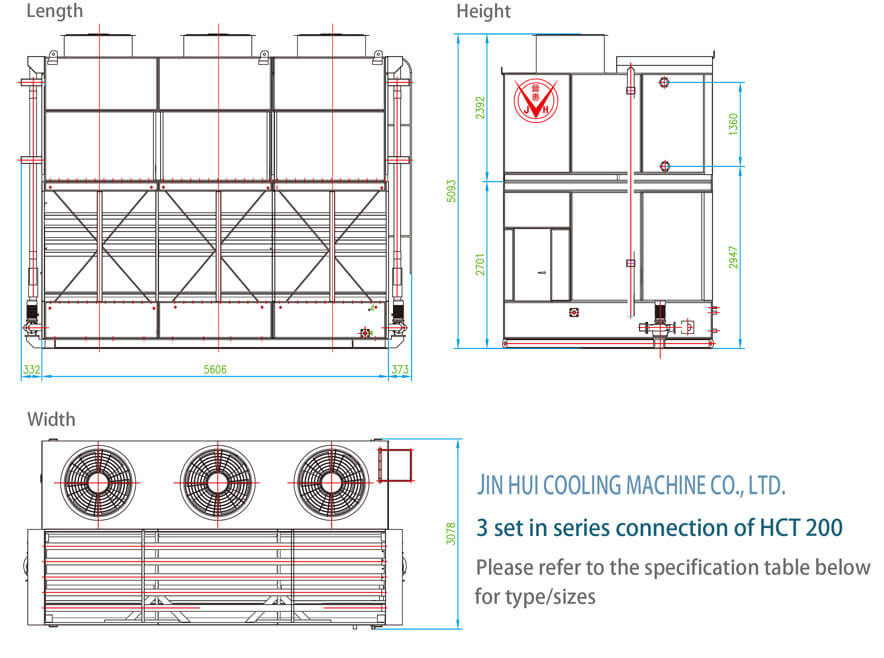

| HCT-250 | 756000 | 150-153 | 3 | 35000x4 | 3 | 120 | 2DN100 | 6050 | 5610x2200x4910 |

| HCT-300 | 900000 | 180-182 | 4 | 45000x4 | 4 | 170 | 2DN125 | 6550 | 5610x2200x4910 |

Above specs are for common use. We can also customize.

Design condition of cooling capacity based on inlet temp 37°C ; outlet 32°C ; wet bulb temp 28°C.

Detail

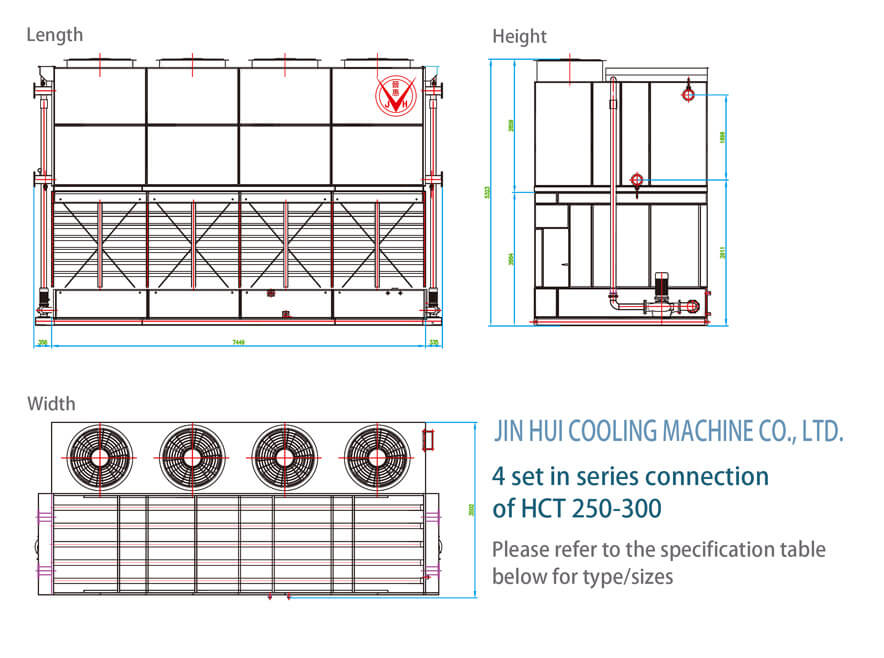

①Cooling fan stack & Motor

HCT's fan motor that adopts aluminum alloy axial fan with direct-joint structure avoids drawbacks from belt transmission. This fan motor possesses lots of advantages such as long-term stability of product, low noise, no transmission loss, high efficiency, low friction between components and low breakdown rate.

HCT's fan motor that adopts aluminum alloy axial fan with direct-joint structure avoids drawbacks from belt transmission. This fan motor possesses lots of advantages such as long-term stability of product, low noise, no transmission loss, high efficiency, low friction between components and low breakdown rate.

③External circulating water spray system

HCT Closed Circuit Cooling Tower uses big flow rate nozzle for outer circulating distribution system. This reduces clogging issues. The nozzle is placed at the top of the device for easy maintenance. Nevertheless, water and wind are designed to operate the same direction with even water distribution to largely decrease dirt attaching coil.

HCT Closed Circuit Cooling Tower uses big flow rate nozzle for outer circulating distribution system. This reduces clogging issues. The nozzle is placed at the top of the device for easy maintenance. Nevertheless, water and wind are designed to operate the same direction with even water distribution to largely decrease dirt attaching coil.

④Heat exchanger

HCT's heat exchange coil made of stainless steel #304 with thickness of 1mm is non-corrosive in most specific regions and extended lifetime. The bevel slope design keeps water out while not in use.

HCT's heat exchange coil made of stainless steel #304 with thickness of 1mm is non-corrosive in most specific regions and extended lifetime. The bevel slope design keeps water out while not in use.

⑦Shell material

HCT's shell material is made of 2mm aluminium-zinc steel plate. This material includes aluminum with anti-corrosion, zinc with anodic treatment and silicon that combines the strength of aluminium-plated steel and zinc-plated steel. The lifetime of the plate is able to reach is 4 to 6 times longer than galvanized plate.

HCT's shell material is made of 2mm aluminium-zinc steel plate. This material includes aluminum with anti-corrosion, zinc with anodic treatment and silicon that combines the strength of aluminium-plated steel and zinc-plated steel. The lifetime of the plate is able to reach is 4 to 6 times longer than galvanized plate.

②Water eliminator、⑤Fill and ⑥Maintenance space

HCT Closed Circuit Cooling Tower is designed with the air and water current flows in the same direction for cooling. ⑤ Fill and heat exchanger coil are separated to ensure that the fill do not block the flow channel. Besides, ② Water eliminators are dischargeable to be convenient to clean regularly and maintain efficiency. Also, ⑥ the internal space are large enough to accommodate maintenance person to execute work.

HCT Closed Circuit Cooling Tower is designed with the air and water current flows in the same direction for cooling. ⑤ Fill and heat exchanger coil are separated to ensure that the fill do not block the flow channel. Besides, ② Water eliminators are dischargeable to be convenient to clean regularly and maintain efficiency. Also, ⑥ the internal space are large enough to accommodate maintenance person to execute work.

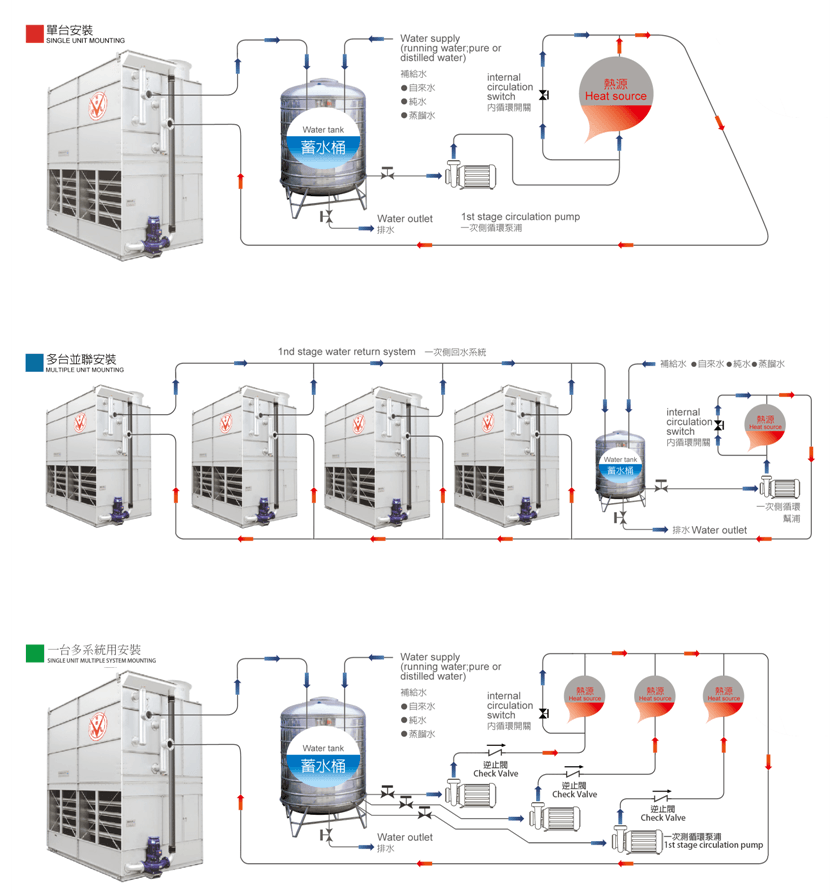

HCT Closed Loop Cooling Tower Pipe Layout