-

WM Series Molding, Shell Tube Heat Exchanger, Tube Cleaner

WM Series Molding, Shell Tube Heat Exchanger, Tube Cleaner

WM Series Molding, Shell Tube Heat Exchanger, Tube Cleaner

WM Series Molding, Shell Tube Heat Exchanger, Tube Cleaner

-

40L FRP Acid tank strong & useful

40L FRP Acid tank strong & useful

40L FRP Acid tank strong & useful

40L FRP Acid tank strong & useful

-

Different types of inlet and outlet pipe

Different types of inlet and outlet pipe

Different types of inlet and outlet pipe

Different types of inlet and outlet pipe

-

Acid true union switch

Acid true union switch

Acid true union switch

Acid true union switch

-

Four carts design a better flexibility

Four carts design a better flexibility

Four carts design a better flexibility

Four carts design a better flexibility

https://cooling-towers.com.tw/product-2/118-heat-exchanger-tube-cleaner/460-wm-series-molding-shell-tube-heat-exchanger-tube-cleaner-75l-135l-min#sigProIdd74e1bc31e

Feature

# 304 stainless steel body

PP Anti-Acid Pump< /blockquote>

F.R.P Water Tank

4 Wheels Trolley

Dismount Union Switch

No-Fuse Breaker

Bottom Drainage

Description

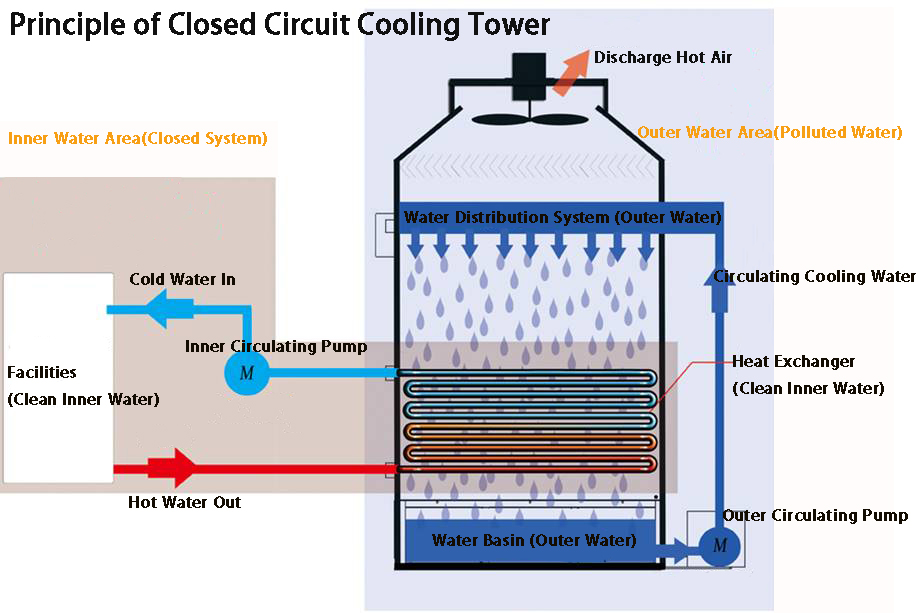

WM Tube Cleaner is professional for cleaning limescale. The WM series is made for the use of chiller, plate heat exchanger and mold that have been blocked by limescale. WM Tube Cleaner is modular equipment that is suitable for cleaning many machines. This tube cleaner is easy to use and durable, customers will no longer have concern with motor rustiness and corrosion problems. Also, its safety design makes sure that the users don’t worry about leakage current or agent spray from cleaning the machine. WM is absolutely your best choice to get rid of limescale.

Application

- Plastic injection machine - Oil temperature cooling system

- Refrigerator condenser, cooler

- Mold cooling water circuit

- Mold temperature controller cooling circuit

- Air compressor cooling system

- Casting system plate type heat exchanger

- Various manufacture facilities cooling system

Specification

| Model number | WM-75 | WM-100 | WM-135 |

| Circulating Water Flow (L/min) | 75 | 100 | 135 |

| Lift (m) | 6.8 | 9.8 | 12.5 |

| Tube Diameter (inch) | 3/4" | 1" | 1" |

| Phase / Frequency / Voltage | single phase voltage: 110V/220V frequency:50/60 | ||

| Net Weight (kg) | 23.5 | ||

| Dimensions (mm) | 600(L)x450(W)x780(H) | ||

| Body Material | # 304 (1.5mm) stainless steel body | ||

| Acid / Alkaline Resistance Pump | PP Acid/alkaline resistance glandless pump | ||

| Water Tank Material | F.R.P Acid / Alkaline Resistance Water Tank,L:250*W:250*H:600* (40Liter) | ||

| water way switch | The switches for the water channels are acid/alkaline resistance and have various tube inlets and outlets. | ||

| Acid/alkaline resistance pump cover | # 304 stainless steel protection cover | ||

| Movable trolley | 4 thickened and reinforced wheels | ||

| Pressure adjustment | Built-in circulating system. It prevents pump from idling and adjusts the pressure of outgoing water. | ||

| Drainage | Bucket and base drainage system | ||

| Power Switch | Shihlin manufactured NFB (No Fuse Breaker) | ||

Details

Machine Housing

Tube Cleaner body that is constructed with 1.5mm thickness Stainless Steel #304 is tough and durable, no worries at motor vibration and agent corrosion.

Tube Cleaner body that is constructed with 1.5mm thickness Stainless Steel #304 is tough and durable, no worries at motor vibration and agent corrosion.

P.P Pump & Cover

WM Tube Cleaner that takes PP non-leak shaft seal pump is able to prevent corrosion from acid washing. Above the pump is Stainless Steel #304 lid to protect the pump against agent spraying.

WM Tube Cleaner that takes PP non-leak shaft seal pump is able to prevent corrosion from acid washing. Above the pump is Stainless Steel #304 lid to protect the pump against agent spraying.

Water Tank & Bottom Drainage

The circulating water tank for WM tube cleaning machine is made with F.R.P acid/alkaline resistance material. The drainage of the water tank is constructed on the side and the bottom for easy maintenance after using.

The circulating water tank for WM tube cleaning machine is made with F.R.P acid/alkaline resistance material. The drainage of the water tank is constructed on the side and the bottom for easy maintenance after using.

Union Switch

WM tube cleaning machine with anti-acid hammer union is suited to different tube diameters.

WM tube cleaning machine with anti-acid hammer union is suited to different tube diameters.

Movable Trolley

WM Tube Cleaning Machine with 4 intensified wheels is designed for easily movable and convenient to load enough water amount.

WM Tube Cleaning Machine with 4 intensified wheels is designed for easily movable and convenient to load enough water amount.

Safety Design

The tube cleaning machine is integrated with an internal circulating system that prevents the pump from idling and controls the pressure of outlet water. To ensure operational safety, the machine is equipped with circuit breaker to avoid electric leakage.

The tube cleaning machine is integrated with an internal circulating system that prevents the pump from idling and controls the pressure of outlet water. To ensure operational safety, the machine is equipped with circuit breaker to avoid electric leakage.

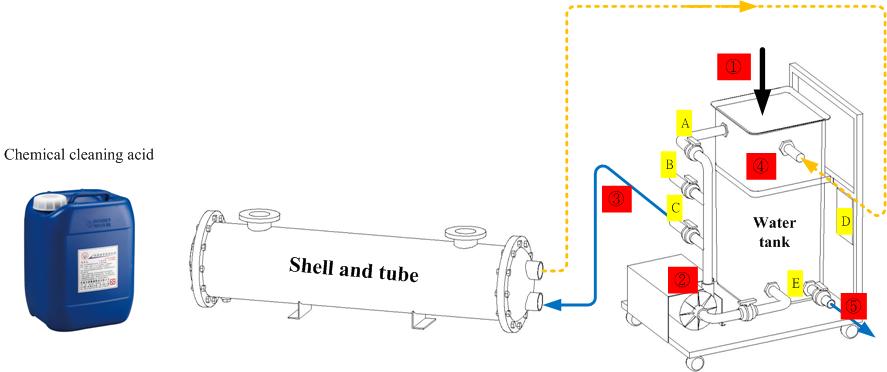

Cleaning Steps

- Pour water and cleaning chemical agent into water tank

- Turn on switch D and activate motor

- Switch on C valve to make solution flow into cooling water circuit

- Finish all above steps, machine will start cleaning up

- Solution with impurities flows back to water tank again

- Repeatedly circulate for 20-30 minutes (operating time depends on condition)

- Turn on E valve to discharge polluted water

- Finish all cleaning steps