-

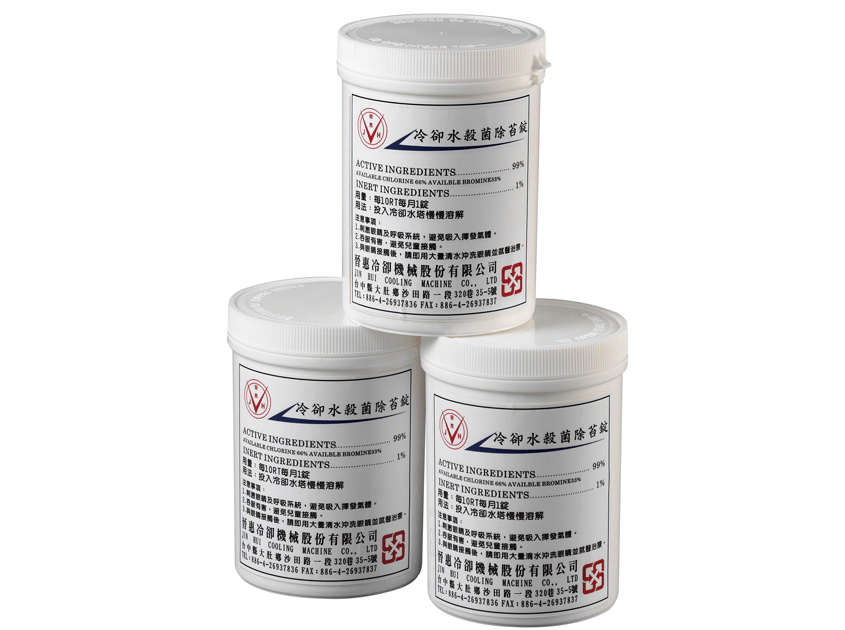

Disinfect/ Moss demolishing tablets (prevent the external circuit from growing moss) 10L/ bucket

Disinfect/ Moss demolishing tablets (prevent the external circuit from growing moss) 10L/ bucket

Disinfect/ Moss demolishing tablets (prevent the external circuit from growing moss) 10L/ bucket

Disinfect/ Moss demolishing tablets (prevent the external circuit from growing moss) 10L/ bucket

-

Eco-friendly high concentrated pipe cleaning fluids (remove limscale of external circuit) 10L/bucket

Eco-friendly high concentrated pipe cleaning fluids (remove limscale of external circuit) 10L/bucket

Eco-friendly high concentrated pipe cleaning fluids (remove limscale of external circuit) 10L/bucket

Eco-friendly high concentrated pipe cleaning fluids (remove limscale of external circuit) 10L/bucket

-

High concentrated anti-corrosion fluids (protect the pipe from corrosion) 5L/bucket

High concentrated anti-corrosion fluids (protect the pipe from corrosion) 5L/bucket

High concentrated anti-corrosion fluids (protect the pipe from corrosion) 5L/bucket

High concentrated anti-corrosion fluids (protect the pipe from corrosion) 5L/bucket

-

-

Disinfect/ Moss demolishing tablets (prevent the external circuit from growing moss) 10L/ bucket

Disinfect/ Moss demolishing tablets (prevent the external circuit from growing moss) 10L/ bucket

Disinfect/ Moss demolishing tablets (prevent the external circuit from growing moss) 10L/ bucket

Disinfect/ Moss demolishing tablets (prevent the external circuit from growing moss) 10L/ bucket

-

Eco-friendly high concentrated pipe cleaning fluids (remove limscale of external circuit) 10L/bucket

Eco-friendly high concentrated pipe cleaning fluids (remove limscale of external circuit) 10L/bucket

Eco-friendly high concentrated pipe cleaning fluids (remove limscale of external circuit) 10L/bucket

Eco-friendly high concentrated pipe cleaning fluids (remove limscale of external circuit) 10L/bucket

-

High concentrated anti-corrosion fluids (protect the pipe from corrosion) 5L/bucket

High concentrated anti-corrosion fluids (protect the pipe from corrosion) 5L/bucket

High concentrated anti-corrosion fluids (protect the pipe from corrosion) 5L/bucket

High concentrated anti-corrosion fluids (protect the pipe from corrosion) 5L/bucket

Maintenance agent for closed circuit cooling tower

The principle of closed circuit cooling tower is to separate internal circuit and external circuit, hence, the containment and limescale are able to be isolated from customer’s equipment. But how to maintain to increase the lifetime of closed circuit cooling tower and heat exchanger?

- External Circuit – Moss Removal

- External Circuit – Limescale Removal

- Internal Circuit – Corrosion Resistance

Introduction of maintenance:

External Circuit – Moss Removal

The closed circuit cooling tower uses the operation of fans to absorb outside air and take the heat away. Although the impurities can be effectively isolated outside by heat exchanger, the dirt still absorb from air intake net. Besides frequently cleaning the basin bottom, it is also a good way to put biocide tablets inside the water basin in order to avoid growing the moss and to lower the potential of producing bacterial.

External Circuit – Limescale Removal

Using Closed Circuit Cooling Tower ensures inner water clean; however, the continuous evaporative cooling contributes to the growth of calcium concentration. When reaching to a certain level, the calcium reacts with heat to form limescale. In order to cope with limescale, the best way to reduce the concentration of calcium concentration is to regularly discharge original water from water basin and exchange new water. But if the surroundings of cooling tower is exceptional, for example, the heat exchanger or fill are attached by limescale, customers are able to use citric acid or calcium carbonate to dissolve limscale for maintenance.

Internal Circuit – Corrosion Resistance

Closed circuit cooling tower separates internal circuit and external circuit. Therefore, there’s no water waste, pollution and calcium concentration in internal circuit contributing to limescale problem. Most users who use closed circuit cooling tower will add in the following water to ensure the cleanness of internal circuit:

- Pure water

- Distilled water

- Tap water

- Ground water

Even though limescale does not build up, cooling water stays in cooling system for long. Because of this, cooling water more or less contacts the air and indirectly produces the corrosion on heat exchange coil. To increase the pipeline's use age, adding some concentrated anti-corrosion agents into internal circuit is a good method to protect metal pipes from corrosion.

Contact Jin Hui

Feel free to contact us for more inquiries with maintenance fluids and maintenance techniques. We are glad to serve you and to ensure your equipment always in stable production.