How does limescale produce?

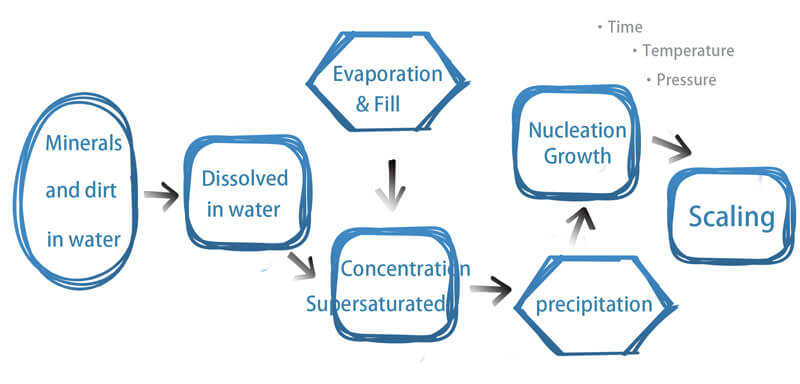

Calcium carbonate, which is a metal ion, exists in underground water and tap water. When exceeding a certain amount of concentration, calcium carbonate will react with heat to form limescale. It is called CaCO3 limescale.

When cooling plastic injection equipment, cooling water circuit will be blocked to result in machine halt. Therefore, customers often ask us how to change water quality or which equipment customers should set up to remove calcium carbonate and limescale. In fact, the reason that limescale builds up on equipment is not only water quality. The most important reason usually comes from cooling tower. (Relationship between limscale and cooling tower?)

How limsescale leads to blockage of equipment?

When cooling tower operates, calcium carbonate water has also been supplying that finally causes the increase in calcium carbonate concentration. While cooling water with high calcium carbonate concentration enters into equipment, it is easy to deposit limescale on heat exchanger and water pipeline. This eventually contributes to decreasing heat transfer efficiency and machine halt.(Limescale leads to power consumption ? )

Cooling tower operates-> Cooling water enters equipment to lower temperature -> Heat evaporates cooling water -> New cooling water is supplied to cooling tower -> Increase in mineral content in water -> Cooling water again enters equipment to lower temperature -> Limescale accumulation -> Decrease the cooling efficiency -> Rise in limescale as times passed -> Cooling water pipeline’s clogged with limescale -> Equipment can’t be lowered temperature

Limescale buildup VS Cooling efficiency Comparison Sheet

| Cooling tower cycle time | Plastic injection cooling water circuit | Cooling efficiency | Calcium carbonate concentration |

| First day | Calcium ion doesn’t calcify | Good | Normal value |

| First week | Calcium ion doesn’t calcify | Good | Normal value |

| First month | Calcium ion start calcifying | Good | Higher than 100 ppm, saturation |

| Third month | Calcium carbonate adhere to heat exchanger | Moderate | Supersaturation, encounter heat to form limescale |

| First year | Blockage on heat exchanger, need acid-washing | Lower | Supersaturation, encounter heat to form limescale |

(PS: Chart is average value, actual status will change based on environment and individual factor)

Contact Jin Hui for inquiry of limescale problem on plastic injection machine

For more limescale solution regarding injection molding machine, please email to us: This email address is being protected from spambots. You need JavaScript enabled to view it. Or contact us by phone: +886-4-26937836 We will offer you fast and professional service!