Annoying limescale problem often appears on cooler, feeder/water jacket, mold, chiller and mold temperature controller. These places greatly affect limescale cooling efficiency. The following are example of limescale problems that plastic injection machine will occur in. ( How limescale produces? ) 。

Oil cooler of injection machine)

If oil cooler of injection machine doesn’t have regular cleaning and maintenance, limescale will deposit on oil cooler, lower heat transfer efficiency of equipment, increase the risk of oil leakage and advance power consumption rate.

If oil cooler of injection machine doesn’t have regular cleaning and maintenance, limescale will deposit on oil cooler, lower heat transfer efficiency of equipment, increase the risk of oil leakage and advance power consumption rate.

Mold

As limescale thickness increases, the cooling time of mold becomes much longer and affects product yield rate. And what is worse is that the mold will be ruined after improper maintenance.

Injection machine feeder

If the feeder/ water jacket is blocked by limescale, melting plastics will occur at chute; and further contribute to insufficient shot.

Chiller Cooler

Thicken limescale makes cooling efficiency become lower, indirectly enhancing energy consumption; even worse the mold cannot be cooled down due to the machine halt caused from poor heat dissipation.

Thicken limescale makes cooling efficiency become lower, indirectly enhancing energy consumption; even worse the mold cannot be cooled down due to the machine halt caused from poor heat dissipation.

Mold temperature controller

If limescale builds up in cooling system, solenoid valve of mold temperature controller will also be accumulated by limescale. In that case, there will be a problem of temperature control for mold injection molding, extrusion, press molding…and so on.

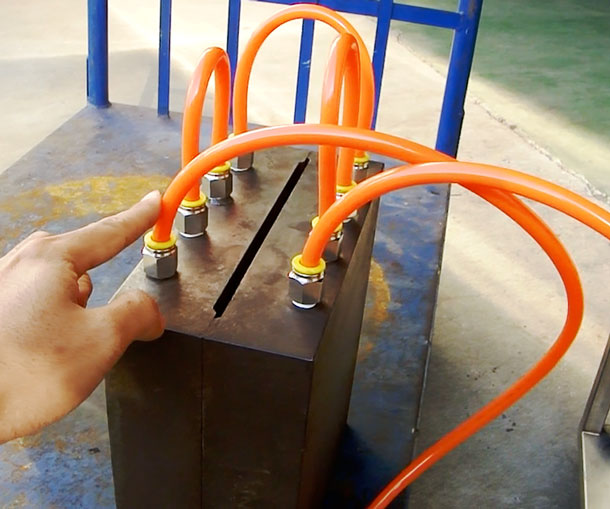

Cooling water circuit

External environment pollution and minerals in water will flow from cooling tower to cooling system water pipes, arriving in cooling facility and each equipment. It finally contributes to unstable temperature control.

External environment pollution and minerals in water will flow from cooling tower to cooling system water pipes, arriving in cooling facility and each equipment. It finally contributes to unstable temperature control.

Contact Jin Hui

For further information, please contact us regarding limescale problem and solution. Welcome to use online consultation service or call us by +886-4-26937836. Directly contact with Jin Hui Cooling Machine. We will offer prompt and professional service for you!!